The Electrical drilling machine designed here is sort of helpful for mechanical workshops. The machine is built with power feed technology is aimed to drill the work up to sure nominal depth, For ex. if a specific piece of job is meant to be trained to a restricted depth, doing it manually consumes ton of your time, as a result of whenever depth must be measured through a crude technique, therefore estimating the drilling depth is sort of sophisticated. For this reason this machine is intended &its mechanical movements square measure restricted by programming the drilling depth through a potentiometer interfaced with microcontroller.

Recommended Project: Front Wheel Steering System with Moveable Headlights

Drilling machine can be defined as a device which is used to drill holes. Drilling machine plays an important role in mechanical workshops. The purpose of this project work is to get hold of complete information pertaining to drilling machines.

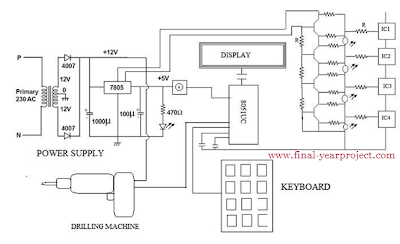

Drilling machine control circuit as shown above consisting of 12 keys is aimed to generate drilling depth information in millimeters. Out of 12 keys, 10 keys are utilized to raise drilling data through numeric numbers of 0 to 9. The 11th key is used as the clear key, & the 12TH key is used as start/go key. After entering the data and by activating the go key, the machine starts & performs the function of drilling. The micro-controller (consisting of a processor, RAM and EPROM, and three ports) takes care of hardware and software when the keyboard is interfaced to it.

Recommended Project: Mechanical Pneumatic And Hydraulic based Projects

In this concept, the microcontroller scans the keys continuously, i.e., the function of programs stored in the EPROM through the keys. The micro-controller monitors the keyboard continuously & detects the activated key automatically. The controller is programmed to store the data of activated keys information into its EPROM.

This project revealed that building a relatively low cost, high precision drilling machine named as “Automatic drilling machine” designed for workshops is aimed to offer benefits to the Industrialists. Since it is a prototype module, the system is designed with a single drilling motor; thereby it can perform the single operation in an instant. To enhance the technology further & to make it more comfortable, drill motors can be increased such that a particular specific task can be achieved with the single machine, therefore it can be used for more applications.

Download

Advertisements:-

![[2025] In-Demand Final Year Projects for Computer Science](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEiPLaQX8S831tmthK7PFgJ6KJQdDJWs5NsY3QREotosR7GUpFsyaw7w80Lrt2nBuz-02KsN5TxtaYtF21u7HLSKFQPxyncmbrOWF3n3DQNiEKCjFb9p4I4-3yYoxKKijLL0lNqaHeCMK1VmZSwEFP2e4esMfpyqMv6iBv6bSe4ZsmmKkOTYEgD47RFYDjE7/s72-c/In-Demand%20Final%20Year%20Projects%20for%20Computer%20Science.jpg)

![Final Year Projects for CSE [2025]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEicwsr89FawhHP1j_XcxTGTU5DxuevpZUQTgFlo_rzjh2YOVGC68ii16T6I7pLcUrR9mu9pVkGsEe_eXBWZhf3fBL-MyLFmw8l0BhRYNOEchX5TlIPCvHoiED-Ix_ZpIbH7T7bklprg5YlabbOX6fPz1Y5-Q4TF7i-MLIEAfbaSjvsJmbnTr91t8i_7Ag/s72-c/final%20year%20projects%20for%20cse.png)

No comments:

Post a Comment